Has your print become loose? Did your nozzle stick to the bed plate? Are you tired of curling, shifting, and warping?

Well, let’s fix that!

When it comes to 3D printing, good bed adhesion is A MUST and we cannot stress that enough. It’s a vital part of the process that affects all the steps after that. If prints fail because of poor adhesion, you go back to square one – wasting all your time, effort, and resources.

After reading this article, you won’t have to deal with those problems ever again.

The 411 on Bed Adhesion

Right off the bat, bed adhesion refers to the ability of the 3D printed plastic to adhere to the build plate while printing. There are different types of 3D printing surfaces to help materials cling to the plate such as aluminum, glass, PET tape, FEI film, etc.

Having good adhesion will give better quality prints and save you all the hassle. Otherise, poor bed adhesion will cause the prints to curl, shift, warp, and eventually fail. Not only will your prints end up bad, you will also waste your time and effort, and start again.

So, what makes a good bed adhesion then?

Three Important Factors of Bed Adhesion

If you’re looking to buy a new 3D bed plate surface, remember these three qualities that you should consider before buying.

- Good Moisture or “Wetting”

Wetting is a term that refers to the ability of the print to stick to the build plate. While printing, filament tries to conform to the build surface when extruded onto a build plate. The print has to stick well for best results.

Some makers use adhesion assistants such as brims, which are added to the base to increase the contact surface area and improve adhesion.

1. Thermal Expansion

The temperature of the bed and enclosure are important aspects of bed adhesion.

This is because if there are differences in temperature between the top and bottom part of a print, it will cause the edges of an object to peel during printing. When 3D printing,a uniform temperature is a must to prevent warming and enhance bed adhesion.

2. Level Printing

We can’t emphasize enough how level printing affects your prints. Checking if the prints are sticking to the build plate is the first thing a maker should check. The distance between the nozzle and the build plate should be consistent and reasonable to adhere filament to the bed.

5 Doable Tips and Tricks to Improve Bed Adhesion

If you’re having issues with your current bed plate, try doing the following tips and tricks!

1. Clean the print surface

Clean the build plate so that there’s no contaminants. This is to ensure the plastic adheres to the build plate. Use rubbing alcohol and microfiber cloth to clean every time before printing. But first, check the build plate material and see if they’re chemically compatible.

2. Configure first layer details

Having a good first layer is crucial to get a good final print. This can be done by tuning the Z offset, the value that tells your printer how far to move the Z-axis from the bed. If the nozzle is too close to the bed, increase the Z-offset. If your first layer is peeling up from the bed, lower the Z offset.

3. Add a heated bed

Keeping the bed temperature higher for a longer period of time will ensure the filament stays molten. This allows the filament to adhere to the bed for a longer period of time.

Too much heat leads to losing dimensional stability, and this happens when the weight of the higher layers squish the lower layers before they have cooled.

Avoid this by closely monitoring your prints and adjust accordingly. If you see the print starting to warp, increase the bed temperature 5 degrees at a time. If it looks melted when finished, try decreasing the bed temperature by 5 degrees.

4. Coat the bed

If you’re still having issues in bed adhesion after doing the previous tips, try any of these techniques:

- Coat the bed with disappearing glue stick

- Use hair sprays, but make sure they only have a few additives to work well for bed adhesion.

- If you have a glass bed, use Wolfbite to help stick your prints to the bed when they warp

- Make a salt solution as it enables a molten filament to wet the build surface through a change in composition

- Apply PEI sheet to your print surface

These budget-friendly solutions are definitely worth the try. See for yourself and let us know what works for you!

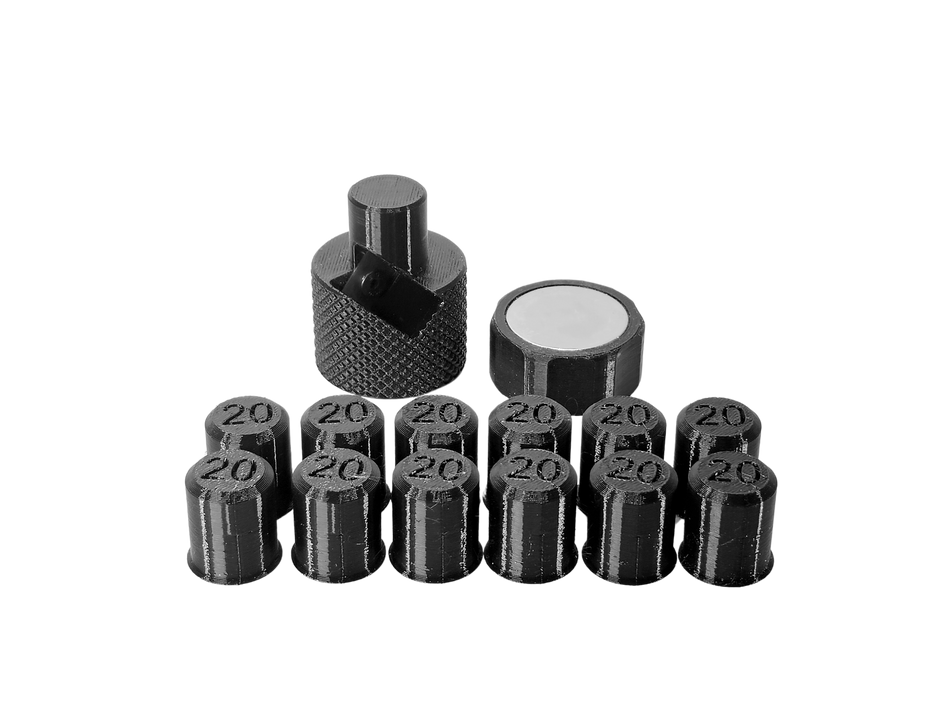

5. Consider using a 3D printed adhesion assistants

Last but not the least, you should try using adhesion assistants such as brims and rafts.

Brims are used to increase the surface area that the print is in contact with. When there’s more contact, there’s more holding for, thus improving print adhesion.

On the other hand, rafts are for removing the print’s bottom layer, replacing it with an easy-to-print platform.They help prevent warping by keeping lingering heat around the print while printing.

The Best Type of Build Plate Surface

Keep in mind that these tips will only be useful if you have the best material for your 3D Print Build Plate Surface. There are built plates that are made of glass, PEI, polypropylene, etc.

Our recommendation? The G10, of course!

G10, also known as Garolite, is a composite material made of fiberglass and epoxy. They’re popular for making circuit boards because they’re excellent insulators, don't absorb water, and have low coefficient thermal expansion.

Here are a few user-benefits you’ll surely love about the G10 build plate:

- Sticky surface when heated, but releases prints like magic

- Works on many types of filaments such as nylon, PLA, TPU, etc.

- Costs less than magnetic and glass beds

With features that address the common pain points in 3D printing, what more could you want? Go ahead and try this buzzworthy build plate surface! Trust us, you don’t want to miss out on this one.

RELATED ARTICLE: Everything You Need To Know about G10

Final Thoughts

To say that “good bed adhesion is key to successful prints” is an understatement. Without it, your prints will shift, curl, warp, and FAIL. Fortunately there are tips and tricks like these that guide us to the right direction to 3D printing success.

If you’re a maker yourself, share some of your tips in the comments below!