Scarring. White spots. Degrading adhesive. Aren’t you tired of dealing with these issues?

PEI users are probably quite familiar with these common challenges. Over time, these issues will affect your work and business operations if you don’t do something about it.

If you are experiencing these, then you’re in luck! We have the perfect build plate option that just might solve your problems. Today, we’re talking about the G10.

But First, What is G10?

G10, or also known as Garolite, is a composite material that is made by curing fiberglass and epoxy under high pressure. They are widely used to make circuit boards mainly because of three reasons:

- It doesn’t absorb water

- It has low coefficient of thermal expansion

- It’s an excellent insulator

Garolite sheets are strong yet lightweight, with engineering and electrical insulating properties. That said, they’re also ideally used in 3D printing.

Now, why are folks raving about this material? How is it different from other print build options?

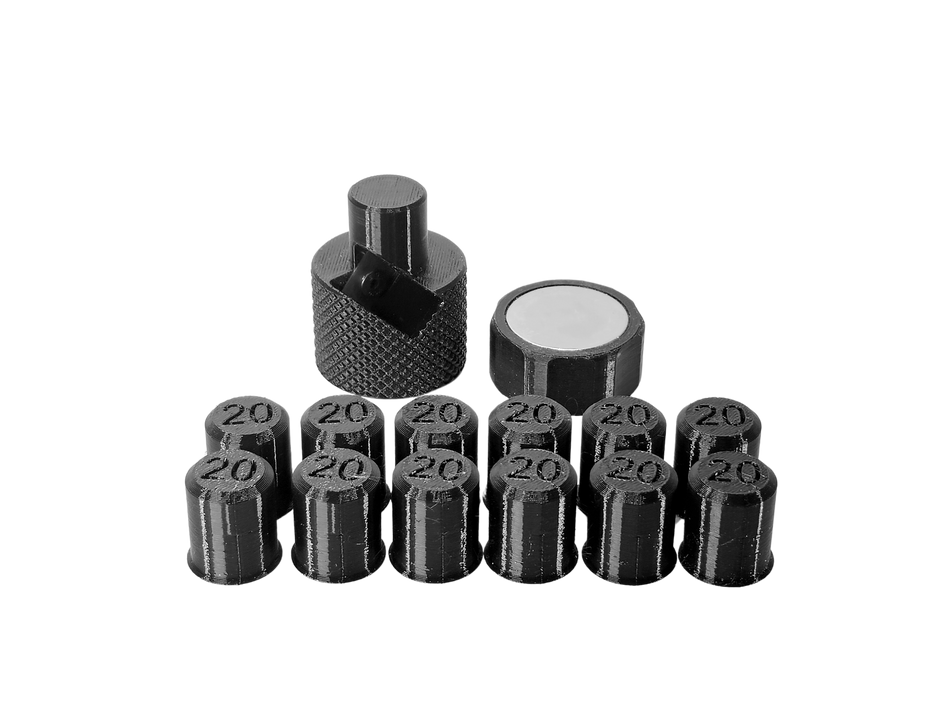

The G10 3D printer build surface plate is taking a lot of attention from other print build plate options because it addresses a common pain point among 3D printing enthusiasts: HASSLE PRINT REMOVAL. We’ve read and watched a lot of reviews, some of which coming from our customers and they all say the same thing:

The surface is sticky when heated but releases prints like magic when the plate has cooled down.

Garolite works well in high temperatures and makes print removal easier when it’s done. They're the perfect solution for hard stick filaments like nylon. However, they also work very well with commonly used filaments such as PLA, PETG, and TPU.

To sum it up, they provide better quality prints thanks to its smooth surface, hassle-free removal, lightweight feature, and overall performance. Check out the next section for more information.

Why is The G10 Worth Using?

A lot of people are talking about G10, and for good reason. Here are 5 user-benefits of using a G10 3D printer surface plate:

1. Releases prints like magic

The G10 holds prints just as good as other build plate surfaces but you can experience the magic when the bed cools down below 70 celsius. The prints self-release without any effort from your end.

If you’re a little pressed for time, there are two other ways to release the prints before it completely cools down. The first option is to remove the sheet, give it a little shake or flex for the parts to cool down faster. Then, pop it off.

The second option is to spray isopropyl alcohol on the corner of the parts. According to Maker’s Muse, this will allow the parts to cool down faster, and the prints will release easily as well.

You can watch the full video by Maker's Muse here:

2. Prints stick wonderfully

Garolite has excellent bed adhesion. Once the bed heats up, your prints stick on the surface like they’re super glued onto it. But when it cools down, the prints just release off the bed.

3. Saves time through easy removal

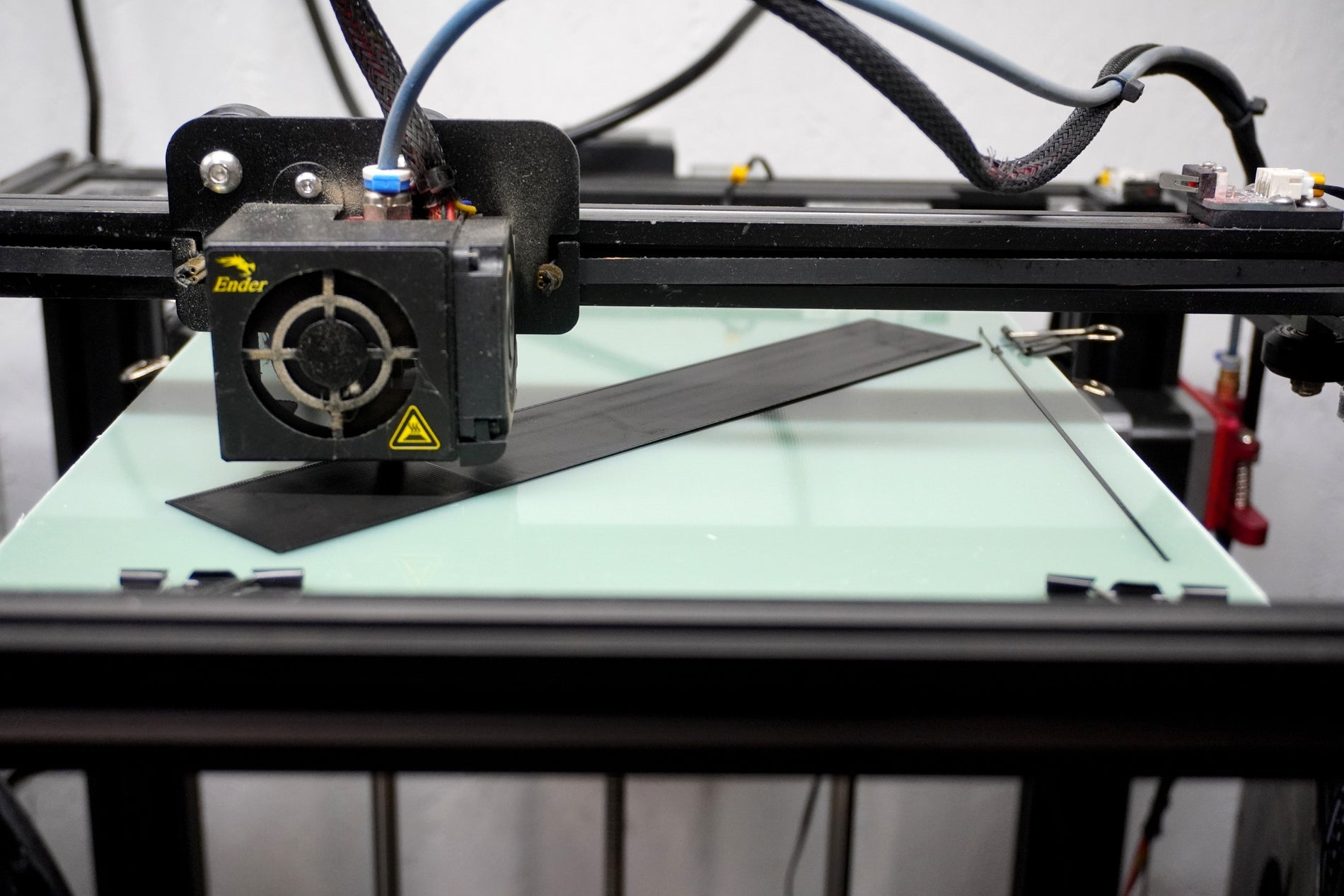

Because of the high temp upgrade and semi-flexible ender, prints release easily, saving a lot of time when removing them from the bed. Plus, rest assured that there will be no warping and no curling. Easy removal of prints without scarring and white spots means you decrease the chances of having do-overs, which is great for those running a business.

4. Works on several filaments other than nylon

While G10 is best used for nylon, they work well on other filaments, too. These other filaments include the different types of PLAs such as:

- Normal PLA

- Polyalchemy PLA

- Fiberology PETG

- rPET

- Essentium PCTG

It also worked very well on more flexible filaments (using a D01) like TPU and high temperature materials like ABS and ASA (just make sure to keep it hot longer).

5. Costs less than glass and magnetic beds

One thing that caught people’s attention is how well Garolite performs during and after printing but it’s also because they’re inexpensive compared to other build plate surfaces.

To compare, our 235mm-sized G10 3D printer build surface is only $24.99 while a similarly sized steel platform with PEI surface costs around $30. With a G10, you get better quality prints at a lower cost and less hassle.

6. Weighs lesser than other build plate options

A standard 1.5mm sheet is lighter compared to glass and sprint steel plates. The lower weight is favorable for printers with a bed that moves for the Y-axis. Aside from that, a lighter load on the printer helps prevent ringing, which usually happens on heavier beds like the Ultrabase Build Plate.

Watch this awesome video discussing G10 vs. Ultrabase Build Plate by JJ Shankles on Youtube.

Lastly, Check Out a Few Tips When Using a Garolite 3D Printing Bed

Before you go, we want to share a few tips and reminders when using a G10 3D printer build surface.

3 Different Ways to Place Your G10 Surface Plate Onto The Bed

You can either clamp it or use an adhesive to keep it on your bed. Another way to do this is to also get a thinner sheet of G10 and attach it to the flex plate system.

Heating Up The Bed Depending on The Filament Used

For nylon, PLA, PETG, rPET, or PCTG, heat up the bed around 55-70 celsius. As for TPU, you don’t need to heat up the bed because it will stick well to the build plate regardless.

A Hack for Printing Nylon on G10

As mentioned earlier, Garolite works best with nylon filament and has no problem sticking to the bed or popping off when it cools down. However, you can still apply a layer of PVA glue onto the bed just to be extra sure that the nylon won’t stick too well on the Garolite sheet. This way, you’ll also have smooth and flat bottoms on your nylon or nylon composite 3D prints.

Final Thoughts

Smooth and sticky surface. Pops off prints like magic. Excellent bed adhesion. Need we say more?

With user-benefits that awesome, no wonder the Garolite build plate material is all the craze right now! Are you really going to miss out ? Check out the G10 3D Printer Build Plate now and never deal with printing problems ever again.