Have you ever seen our bullet holders, castle dice towers, and wheelchair handle grips? These are all created with 3D printing technology. Thanks to this innovative technology, 3D printing has changed the game in manufacturing, prototyping, and home crafting.

One crucial part of the 3D printing process is the build plate, also known as a print bed. It's the foundation upon which your 3D prints take shape, playing a critical role in the success of your printing endeavors. There are many types of build plates, each with its own set of features and made of different materials.

In this article, we will delve into five different types of 3D print build plates. Please be guided by the legend measuring each build type's adhesion strength below:

G10 Garolite Build Plates

Adhesion Strength: 🌟🌟🌟

If there's one build plate you want to get, the G10 3D printer build plate is your best option. This type of build plate addresses one common pain point among 3D printing users, which is the difficulty in removing prints from the build plates.

The G in G10 stands for Garolite, and it's known to work very well in high temperatures, which is why print removal is easy. They're the ideal build plate for hard stick filaments such as PLA, PETG, and TPU.

If you have a Bambu printer, you can also check out the Bambu 3D print build plate. It's similar to the G10 build plate but specifically for Bambu printers.

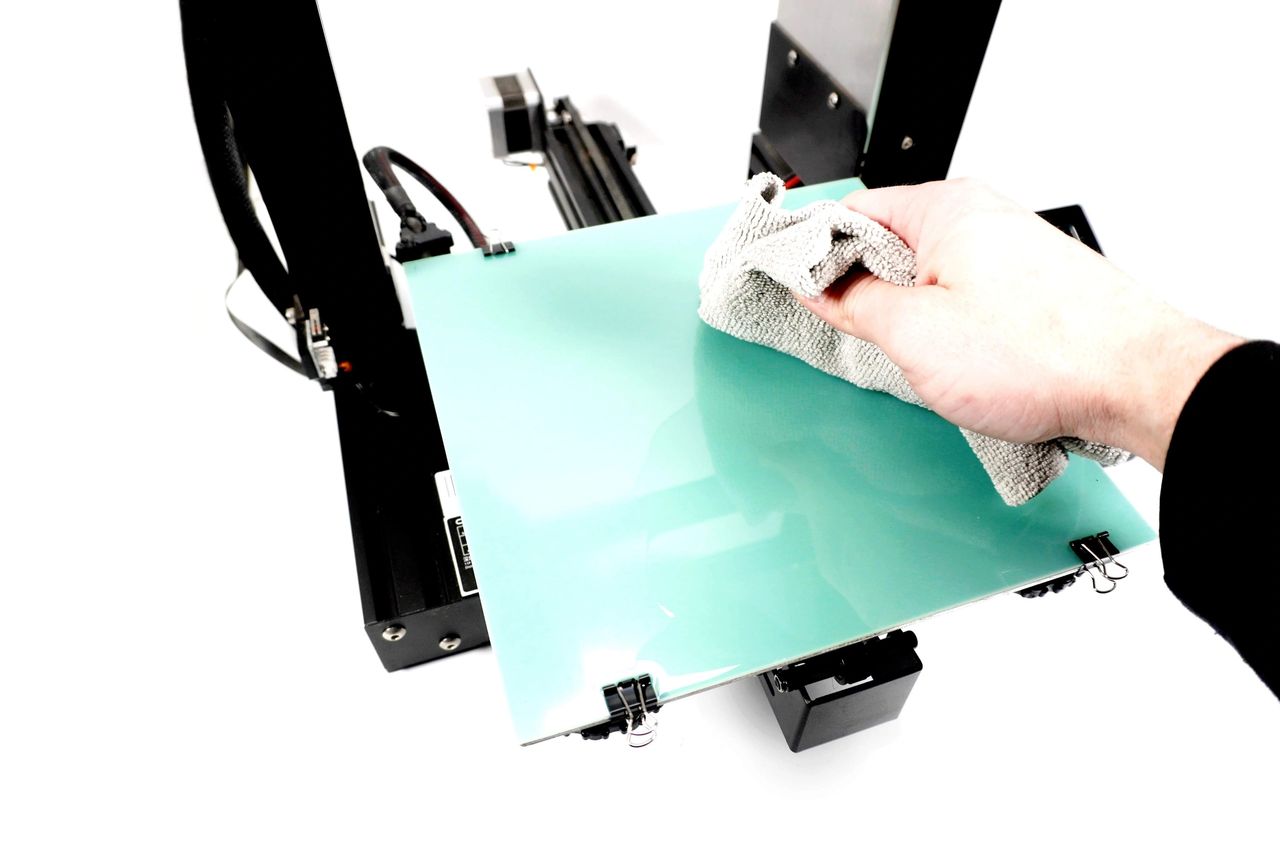

Glass Build Plates

Adhesion Strength: 🌟

Glass is the most common and easily available type of 3D print bed available on most printers. It has a smooth and flat surface, which is ideal for easy-to-print filaments like PLA. However, many users comment that glass print beds have low adhesion strength. This can lead to issues like warping, lifting, and failed prints when using ABS, PETG, or nylon on glass build plates.

PEI (Polyetherimide) Build Plates

Adhesion Strength: 🌟🌟🌟

The PEI build plate is known to have better adhesion strength and is often used for printing all kinds of filaments except for nylon. It's best to use PEI surfaces if you want good adhesion without needing heated build plates. However, if you still need more grip, there are powder-coated PEI builds in the market as well.

In relation to PEI, you can also opt for Flexible Build Plates, a newer addition to the 3D printing scene. These plates are typically made from materials like spring steel coated with PEI, offering an advantage that allows you to remove prints easily by flexing the plate, without any damage.

Polypropylene Build Plates

Adhesion Strength: 🌟🌟

Another versatile type of 3D print build plate is Polypropylene. People use this for almost all filaments except nylon and polycarbonate. Compared to glass, this one is flatter, lighter, and has more promising adhesion features.

Magnetic Build Plates

Adhesion Strength: 🌟🌟

Magnetic build plates are making a name for themselves in the 3D printing community. They are easy to install, have good adhesion, fast heat conduction, and an easy removal feature. Magnetic build plates have a special coating layer, which makes filaments stick to the printed bed easily and reduces warping. Besides that, they're removable and flexible for easy removal of prints. Lastly, their great thermal conductivity speeds up heating time and reduces printing waiting time.

Final Thoughts

Choosing your 3D print build plate is the make-or-break moment of your 3D printing experience. Each type of build plate has its own advantages and disadvantages, and the ideal one depends on your printing needs and preferences. Whether you choose glass, PEI, flexible, magnetic, or a specialized option like a G10 Garolite, understanding the characteristics of each type will help you achieve better 3D printing results.