Is there anybody who hasn’t heard about 3D printing yet? If there are, you should know that 3D printing is an awesome technology that has become highly accessible to hobbyists and professionals alike. However, like any other technology, you’ll inevitably face some challenges that may affect the quality of your prints.

In this troubleshooting guide for beginners, we’ll walk you through the common issues that 3D printer enthusiasts encounter and provide practical solutions to these problems.

Poor Adhesion

One issue that enthusiasts face very often is poor adhesion between the first layer and the print bed. The key here is to ensure that the print bed is clean and level. Adjust the bed leveling screws or use a bed leveling sensor if available. Additionally, depending on the material of your surface build plate, applying a thin layer of adhesive material such as glue stick or painter’s tape can enhance bed adhesion.

Layer Adhesion Problems

Aside from poor adhesion, you as a user might also experience weak layer adhesion. This issue can lead to prints that easily break apart. One way to fix this is to adjust the print temperature settings for the extruder and heated bed, and the printing speed as well. Aside from tweaking with settings in the printer while you’re working, proper storage of filament can also avoid this problem. Make sure to store the filament in a dry environment to prevent moisture absorption, which may compromise layer adhesion.

Extrusion Issues

Another common issue when 3D printing involves extrusion of the filament. Inconsistent extrusion can result in gaps or irregularities in the printed layers. When this happens, you can inspect for any filament jams, make sure the filament diameter matches the printer settings, and confirm that the extruder gear is clean and properly tensioned.

Nozzle Clogs

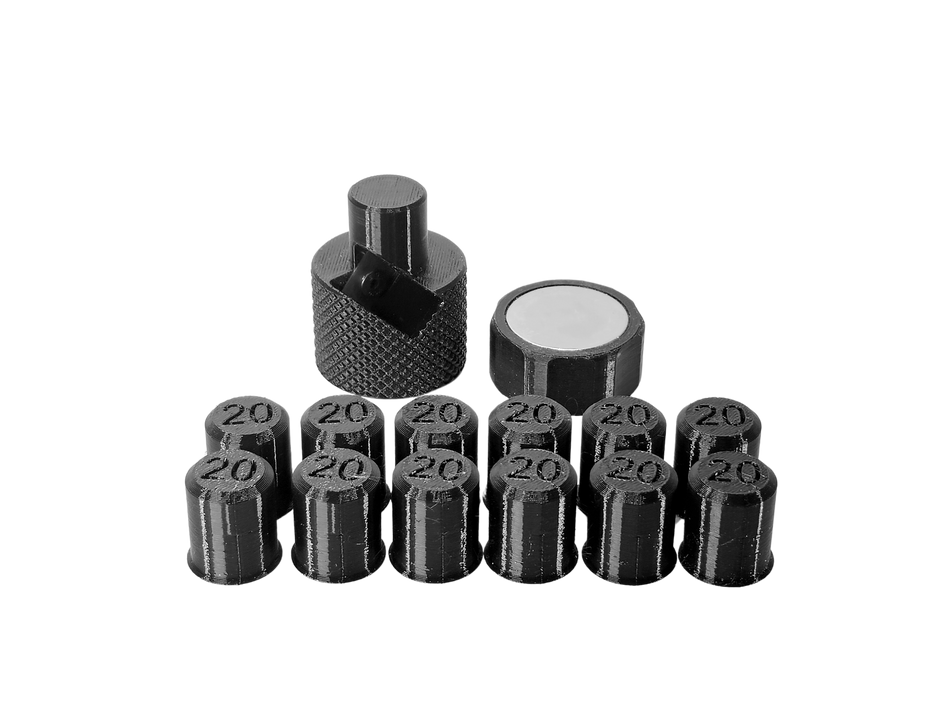

Related to extrusion issues, you might also face the issue of clogging in the nozzle. Clogs in the nozzle can disrupt filament flow and lead to failed prints. The best way to avoid this problem is to clean the nozzle regularly. You can use a fine wire or specialized cleaning tools like this one:

3D Printer Extruder Filament Declogging & Cleaning Tool

Stringing and Oozing

Sometimes, the nozzle moves between different parts of the print. When this happens, optimize the retraction settings in the slicer software. Experiment with retraction distance and speed to find the optimal values for your printer and filament. Additionally, make sure that the hotend is calibrated properly to prevent excessive oozing.

Print Warping

One of the most frustrating issues when 3D printing is warping. Warping occurs when the edges of a print lift or curl, which is caused by uneven cooling or temperature fluctuations. What you can do to avoid this is to use a heated bed to maintain a consistent temperature. Additionally, consider enclosing the printer to create a stable printing environment.

Here are two things you can also try:

- Apply brim or raft to the print to help improve adhesion and reduce warping.

- Switch to G10 (Garolite) 3D printer build plate as this type of build plate has insulating properties which reduces the risk of warping and curling.

3D Printer Build Plate Fiberglass G10 Garolite

Final Thoughts

Troubleshooting 3D printing issues is part of the learning process, and with a systematic approach, many challenges can be overcome. Regular maintenance, proper calibration, and a keen understanding of your specific 3D printer's characteristics are key to achieving consistent and high-quality prints. By addressing common problems and fine-tuning settings, enthusiasts can unlock the full potential of their 3D printers and enjoy a rewarding printing experience.