Getting into the 3D printing scene? Well, buckle up for an exciting ride ahead of you. You’ll soon be creating everything you need from scratch, exactly how you want it!

However, we gotta start somewhere.

To get you started in your 3D printing journey, let’s equip you with the basics of 3D printing: parts of a 3D printer. As a bonus, we’ll also share some things and tools you need to make your experience more seamless.

Extruder

Without an extruder, it’s impossible to turn those plans into prints. The extruder is the device that is responsible for feeding and melting the filament material before depositing it layer by layer to create the 3D prints. You’ll find the extruder in the hotend where it features a motor-driven gear mechanism that grips the filament and pushes it into the heated nozzle. Then, the nozzle heats the filament to its melting point, making it flow smoothly onto the print bed.

Its precision and reliability greatly impacts the quality of the final print, making it a key element in the overall performance of a 3D printer.

Bowden Tube

A Bowden tube in a 3D printer functions as a channel for the melted filament to pass through from the hotend to the extruder. In direct drive systems, the extruder is mounted on the moving print head while in a Bowden setup, a remote extruder is often located near the printer’s frame.

How it works is that the filament is fed through the Bowden tube, which guides it to the hotend where it’s melted and deposited onto the print bed.

The most helpful feature of the Bowden tube is that it helps reduce the moving mass on the print head, allowing for faster and more precise movements during printing. However, there may be challenges related to filament retraction that will affect the printer’s ability to handle flexible filaments. The trick is to find a balance between the advantages and limitations of a Bowden tube to achieve optimal 3D printing performance.

The hot end is exactly as the name suggests, a hot end – and it’s where the filament is melted and extruded through a nozzle. The whole assembly consists of a feed tube, a heat sink, a thermal barrier tube, a heat block, and the nozzle.

Since this is a major part of the 3D printing process, you will eventually experience clogging in the extruder and/or nozzle area due to “heat creep”. This occurs when the filament swells in the hot end due to inadequate cooling. Sometimes, clogging may also be caused by a buildup of filament residue or dust particles that block the nozzle opening.

All these issues, if not addressed, could lead to uneven flow of filament which gives you poor print quality. That’s why we recommend keeping a 3D printer declogging tool in handy at all times. It’s the quick & easy fix to avoid the hassle!

Endstop Switches

The purpose of endstop switches in the 3D printer is to signal the printer when a moving axis (print head or bed) reaches a specific point. These are positioned at the ends of each axis playing an important role in defining the print area and preventing the printer from moving beyond its designated printing area. Endstop switches allow the printer to understand its spatial orientation and effectively execute precise and repeatable movements during each print job.

Controller LCD

Also known as the display screen, the controller LCD is the user interface on a 3D printer. It provides real-time information and control options necessary for printing. You can monitor print progress, adjust settings, and initiate actions in this panel.

Heated Bed

Also known as print bed, this is the part that the object being printed rests on. The way it works is that the print bed moves down as each layer of filament is extruded. This plays a huge role in the printing process which is why it’s important to choose the best kind, to get quality prints.

To name a few features to look out for when looking for the best print bed to purchase, they should:

-

Have a smooth surface

-

Have good print bed should have excellent adhesion properties

-

Have equal heat distribution

There are so many materials that make up print beds but the three most common ones are aluminum, glass, and G10 (garolite) build plates.

Bed Leveling Screws

Bed leveling screws are critical parts of a 3D printer’s build platform. They are designed to ensure a flat and even surface for precise printing. The screws are located below the print bed and they allow manual adjusting of the bed at your preferred height. Without bed leveling screws, you’re more likely to experience issues such as uneven layers, adhesion problems, and print distortions. Regular calibration and adjustment of these screws are essential to produce the best prints.

Get Started With These Two Items

G10 (Garloite) 3D Printer Build Plate

If you want to get quality prints while having a great 3D printing experience, using a high-quality and efficient build plate is key.

The G10 3D printer build plate is one of the best in the market. It’s easy to work with and has all the good qualities a user could ever ask for, such excellent bed adhesion and hassle-free print removal process. You also don’t need to worry about warping and curling which is a common problem when 3D printing.

All these features owe a huge thanks to Garolite, a composite yet semi-flexible material with engineering and electrical properties. While there are many different types of build plates out there, this G10 3D printer build plate is worth a try, and definitely a keeper!

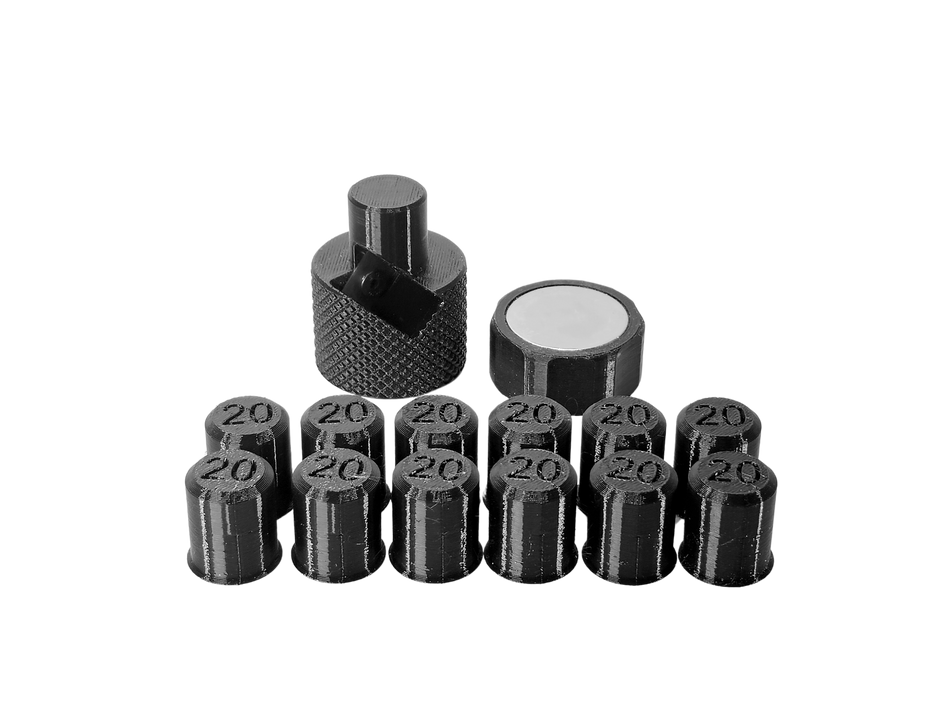

Extruder Filament Declogging & Cleaning Tool

As mentioned earlier, another common problem that people encounter is the clogging of the extruder. But don’t let that faze you, we have a quick and easy solution to this problem!

Our Declogging & Cleaning Tool is your savior when filament clogging occurs in your extruder. It’s a long, thin rod that is designed to be inserted seamlessly into your 3D printer’s nozzle for easier and faster cleaning and unclogging. After a minute or two, your printer will be up and running again.

Make sure to keep this thing in handy when doing some awesome 3D printing work!