About

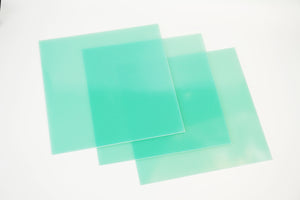

*SCRATCHED OR SCUFFED* ---NO INTERFERENCE WITH FUNCTIONALITY. SOME SCRATCHES MAY SHOW IN PRINTS.

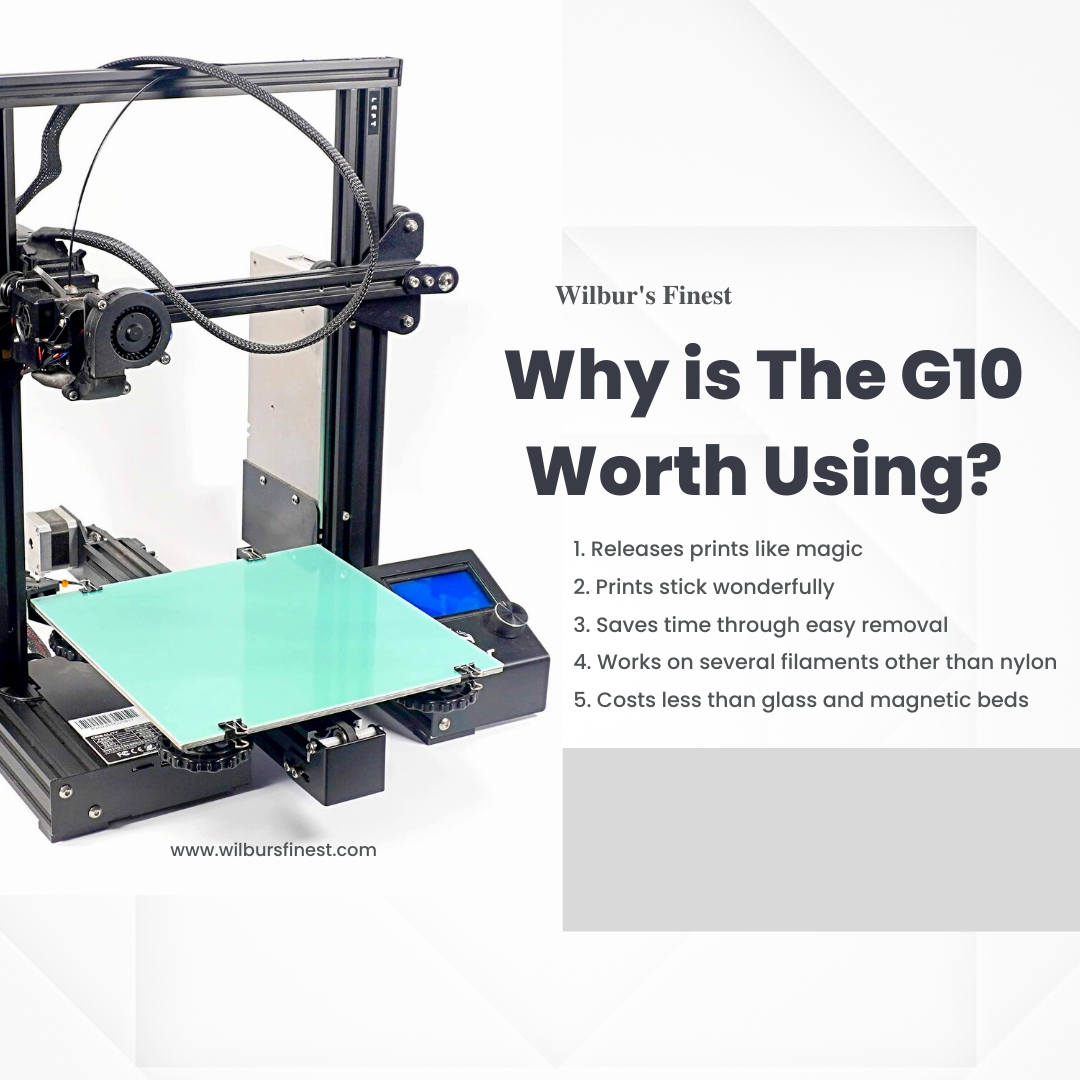

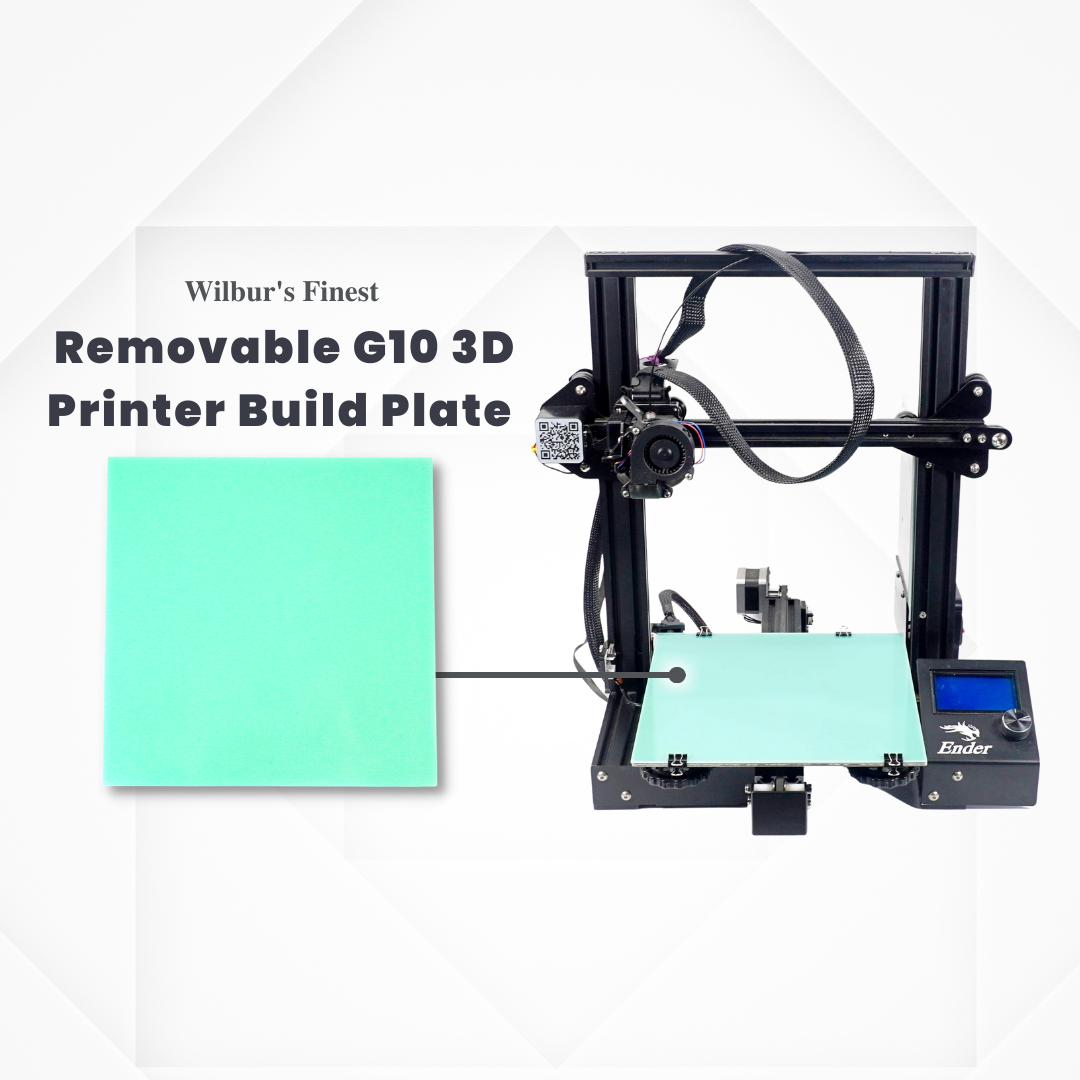

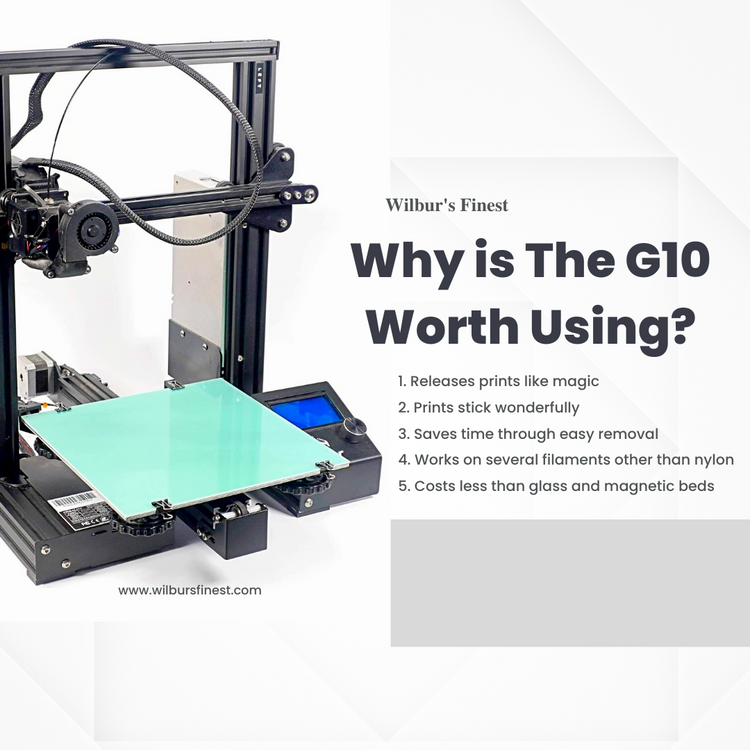

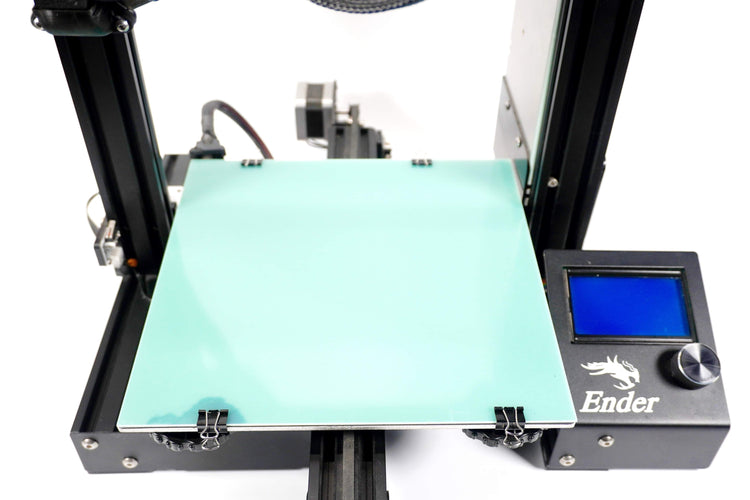

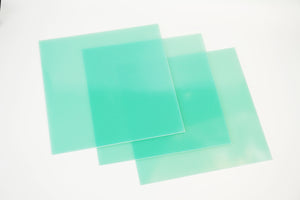

3D Printer Build Surface Plate High Temp Upgrade Semi Flexible Ender 3 235mm 9.25" Fiberglass G10 Garolite Nylon PETG ABS PLA TPU PEEK PEKK ULTEM CF VAAPR

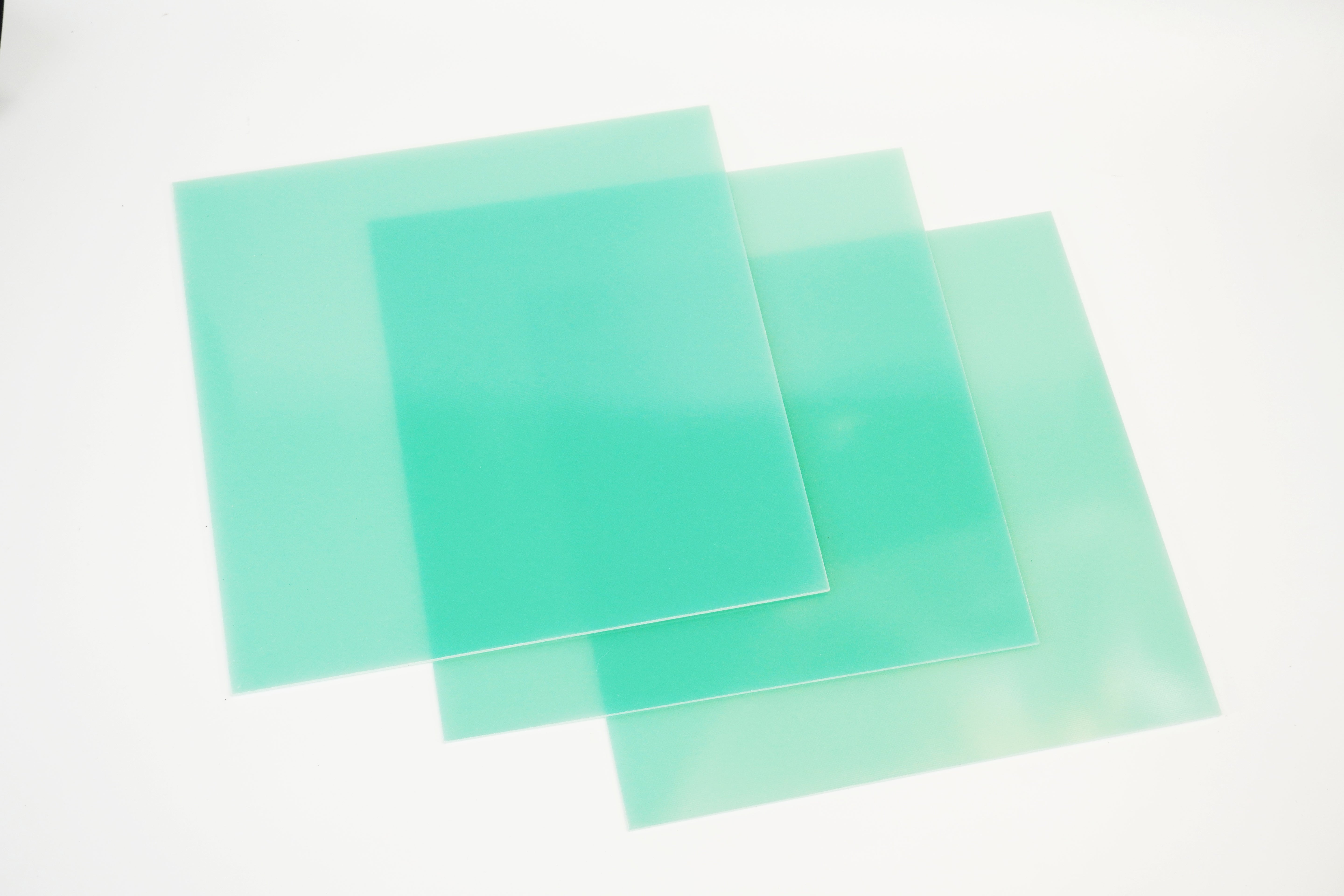

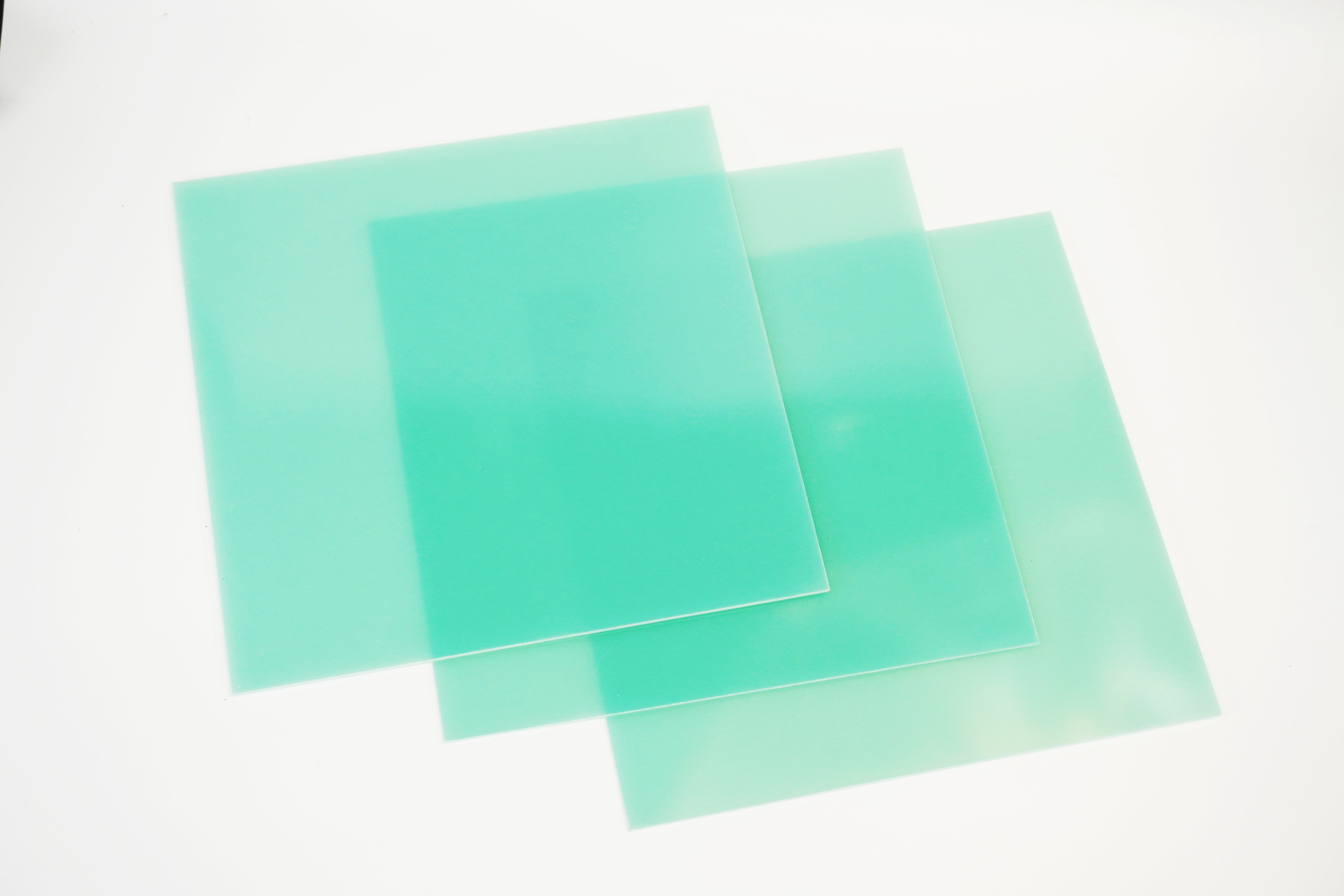

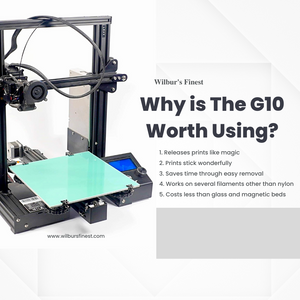

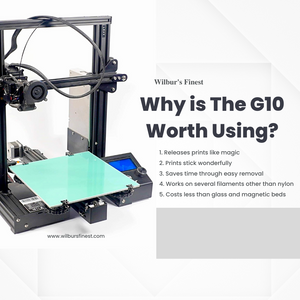

- GET HIGH-QUALITY PRINTS: This 2mm-thick Garolite 3D printer build plate is made of Garolite, a composite and semi-flexible material made by curing fiberglass and epoxy under high pressure. Thus, providing better quality prints thanks to its smooth surface, hassle-free removal, lightweight feature, and overall performance.

- WHY CHOOSE GAROLITE? Strong, lightweight, and has engineering and electrical insulating properties.

- EASY PRINT REMOVAL & EXCELLENT BED ADHESION: Once the bed heats up, your prints stick on the surface like they’re super glued onto it. But when it cools down, the prints just release off the bed.

- TIME EFFICIENT: Because of the high temp upgrade and semi-flexible ender, prints release easily, saving a lot of time when removing them from the bed. Plus, rest assured that there will be no warping and no curling.

- FILAMENT COMPATIBILITY: Best used for nylon, but also works well with PLA, PETG, and TPU. For high temperature materials like ABS and ASA, make sure to keep the bed hot for longer.

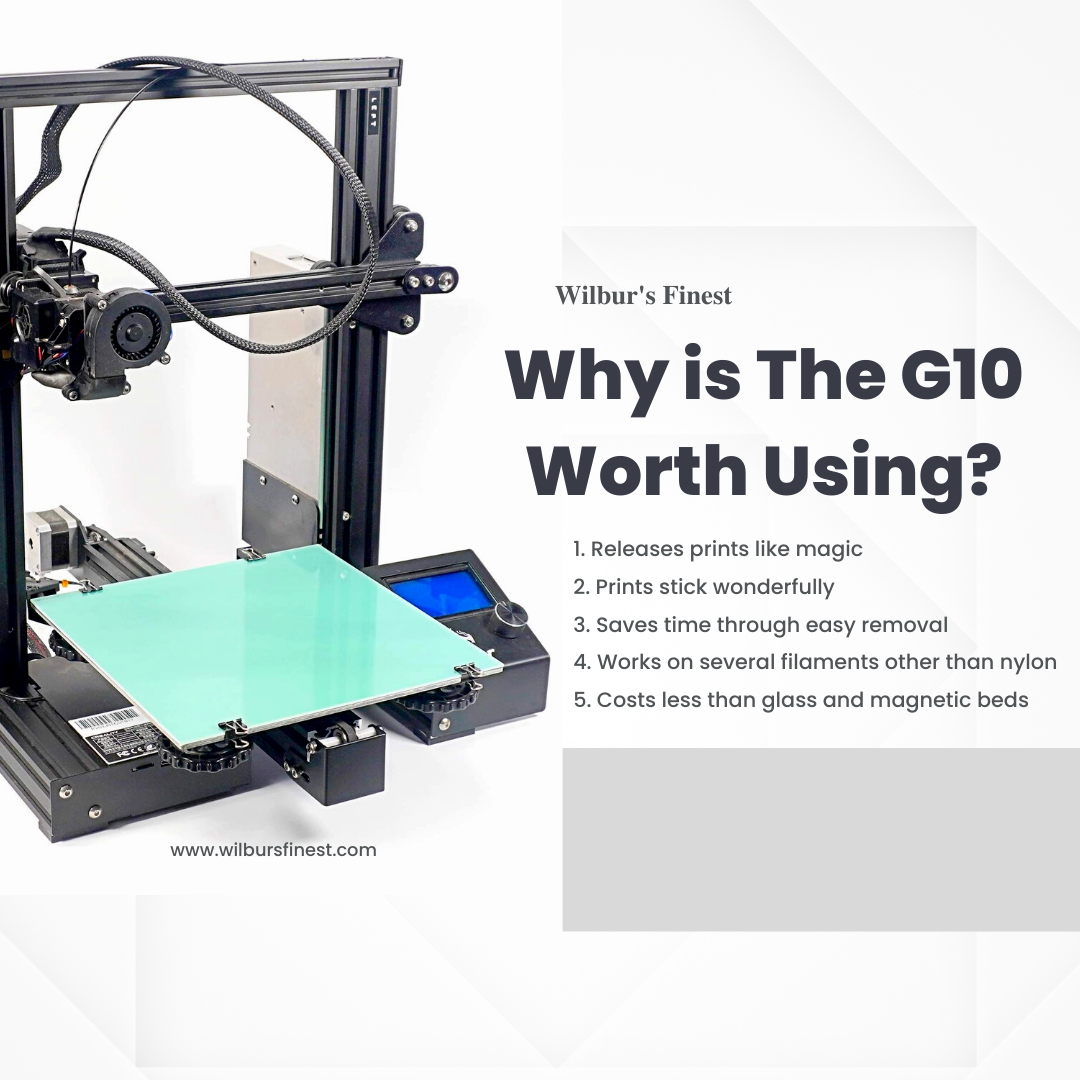

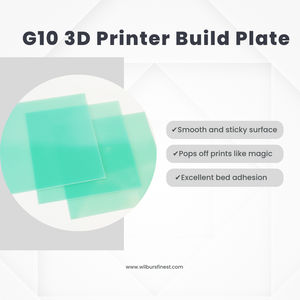

Best Material for 3D Print Build Plates

Garolite is a composite yet semi-flexible material that is reliably strong, lightweight, and has engineering and electrical properties.

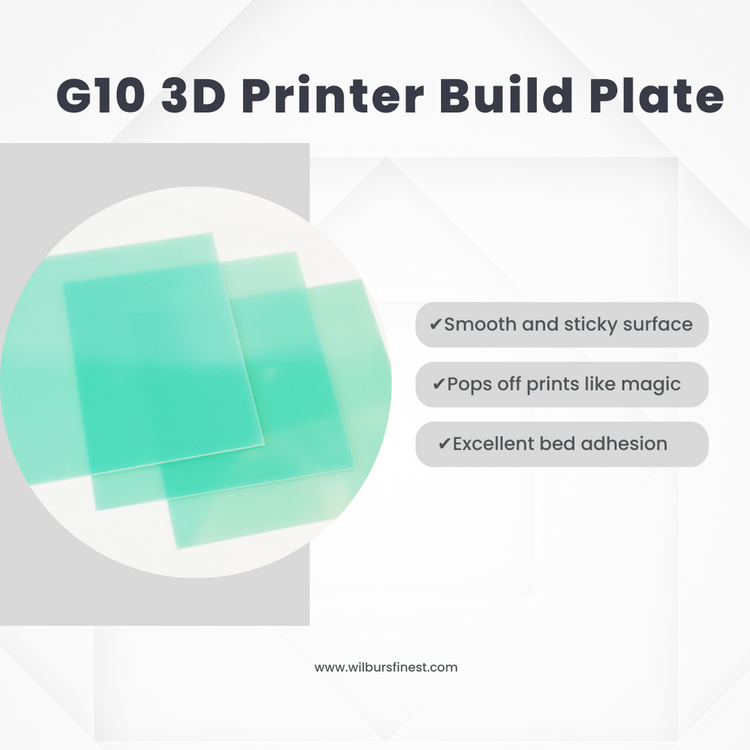

Excellent Bed Adhesion

As soon as the bed heats up, your prints adhere to the surface like super glue. However, once it cools down, the prints release easily like magic.

Hassle-free Print Removal

Prints on the G10 hold up just as well as other build plate surfaces, but you'll get the most out of it when the bed cools down below 70 degrees Celsius wherein prints release themselves effortlessly off the bed.

No Warping and Curling

Easy removal of prints without scarring and white spots means you decrease the chances of having do-overs, which is great for those running a business.

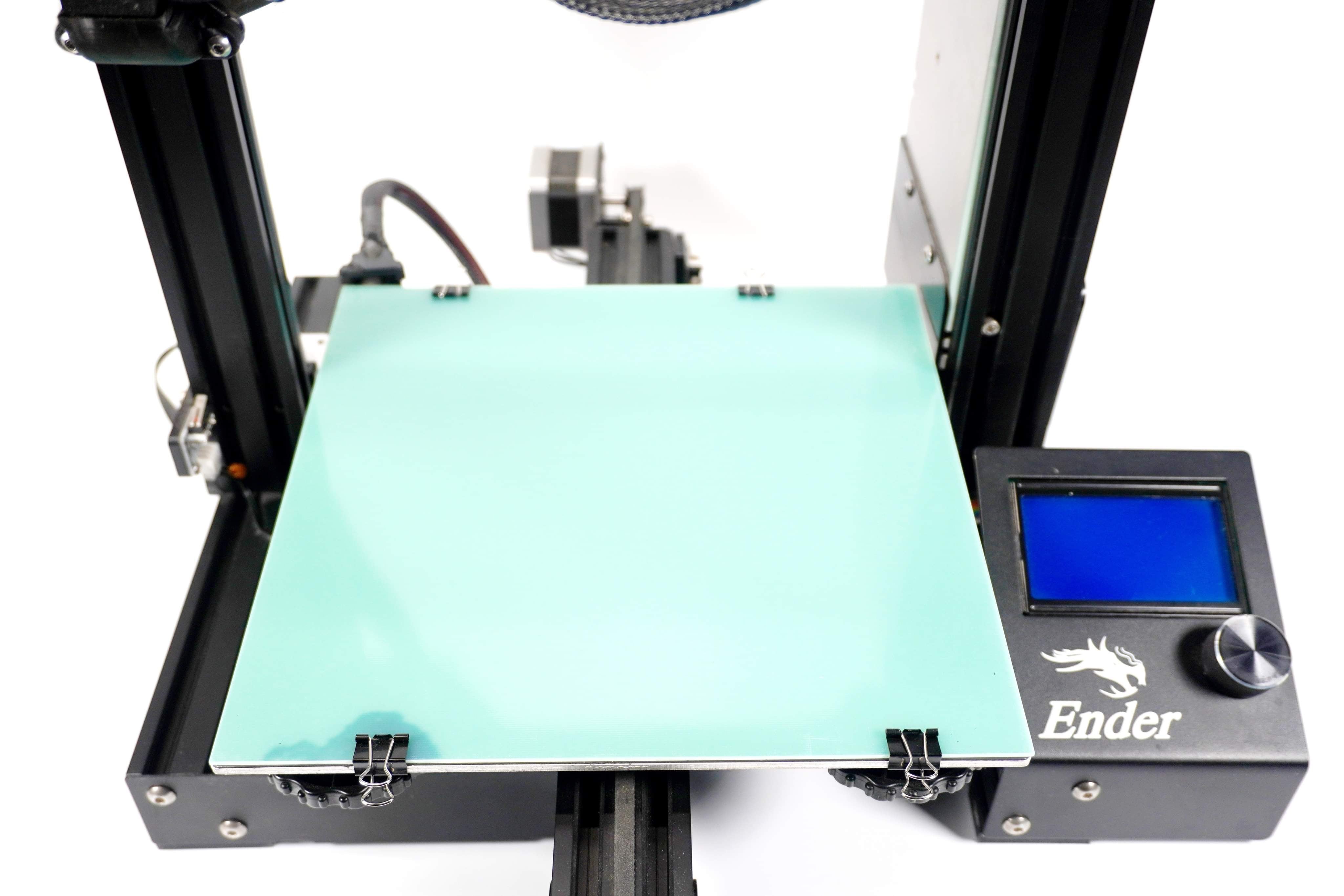

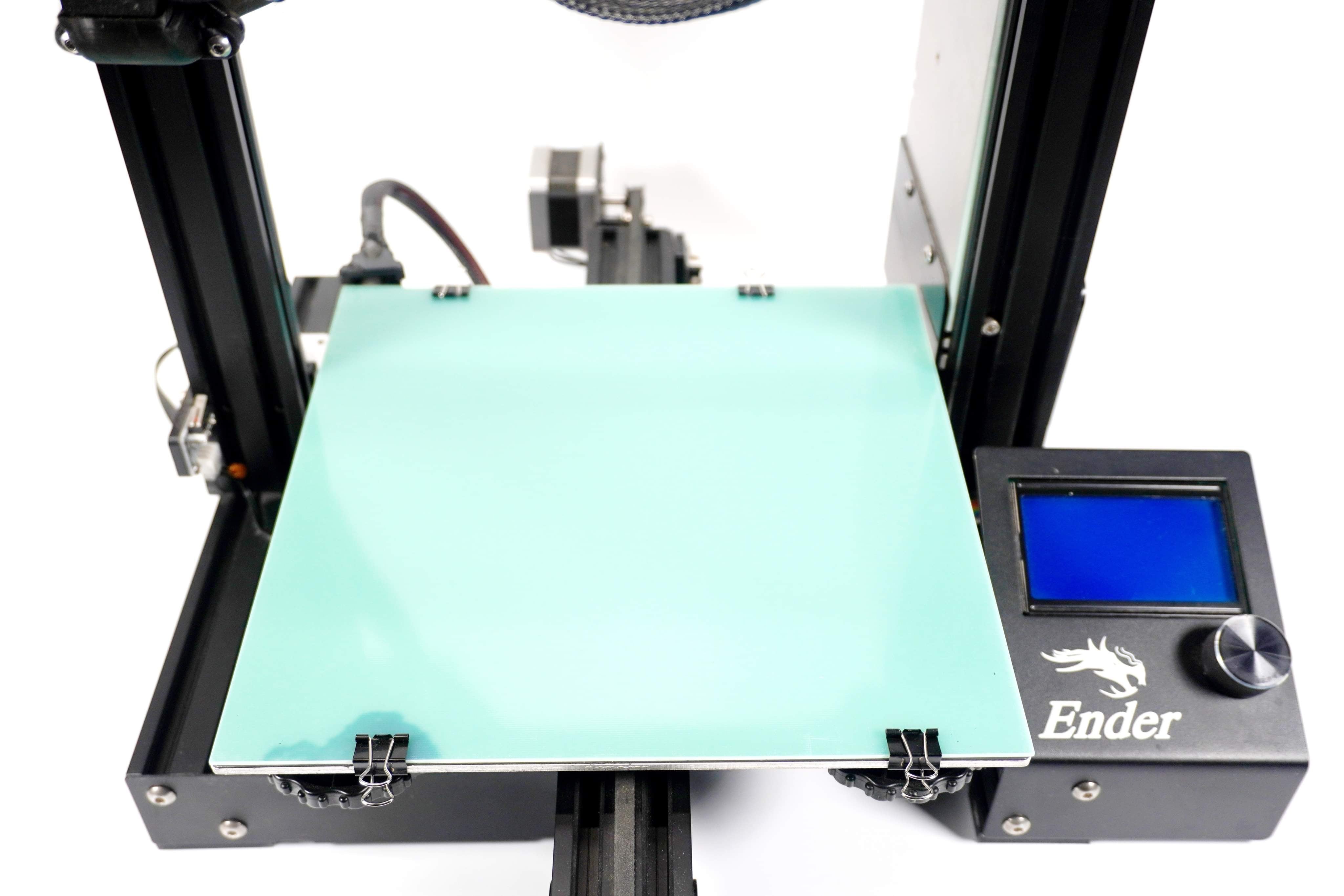

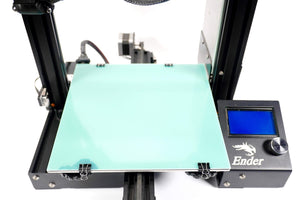

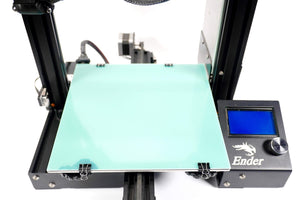

Easy Installation

Install in just 5 steps. Clean, align, clip, clean again, and start printing!

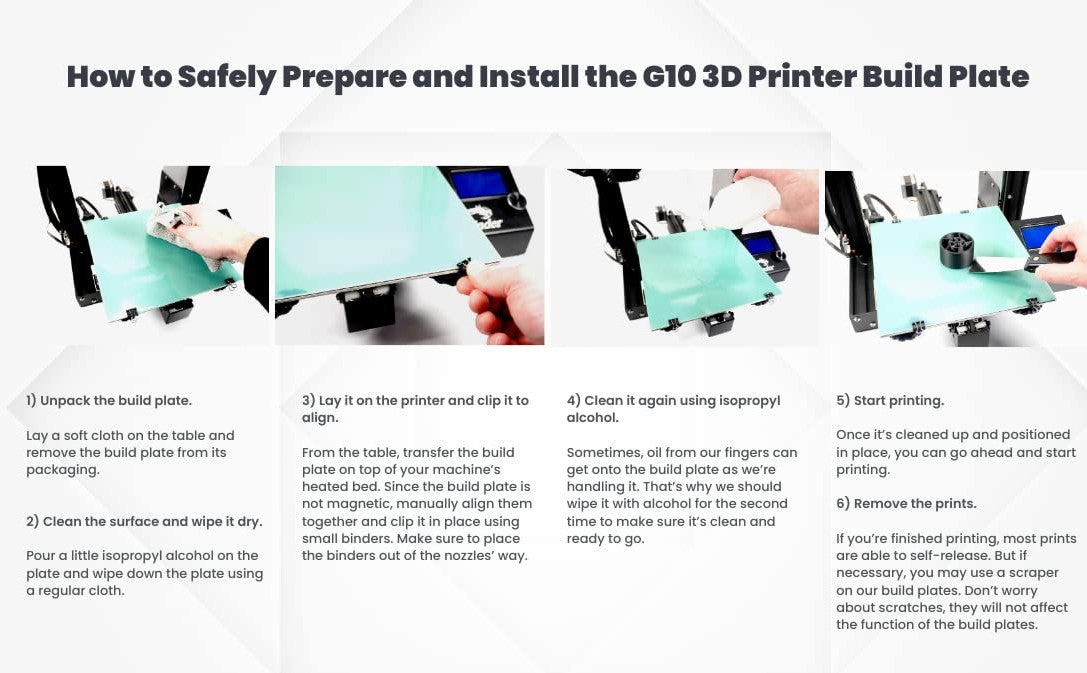

How to Install the G10 3D Printer Build Plate:

- Pour isopropyl alcohol and wipe it down with cloth.

- Lay it on the printer, on top of the heated bed.

- Align it with the heated bed, and clip it using small binder clips.

- Clean it again using isopropyl alcohol and cloth.

- Start printing.

How to Remove Prints:

Most prints are able to self-release, especially with the G10. But if necessary, you may use a scraper on our build plates. Don’t worry about scratches, they will not affect the function of the build plates.

*SCRATCHED OR SCUFFED* ---NO INTERFERENCE WITH FUNCTIONALITY. SOME SCRATCHES MAY SHOW IN PRINTS.

3D Printer Build Surface Plate High Temp Upgrade Semi Flexible Ender 3 235mm 9.25" Fiberglass G10 Garolite Nylon PETG ABS PLA TPU PEEK PEKK ULTEM CF VAAPR

- GET HIGH-QUALITY PRINTS: This 2mm-thick Garolite 3D printer build plate is made of Garolite, a composite and semi-flexible material made by curing fiberglass and epoxy under high pressure. Thus, providing better quality prints thanks to its smooth surface, hassle-free removal, lightweight feature, and overall performance.

- WHY CHOOSE GAROLITE? Strong, lightweight, and has engineering and electrical insulating properties.

- EASY PRINT REMOVAL & EXCELLENT BED ADHESION: Once the bed heats up, your prints stick on the surface like they’re super glued onto it. But when it cools down, the prints just release off the bed.

- TIME EFFICIENT: Because of the high temp upgrade and semi-flexible ender, prints release easily, saving a lot of time when removing them from the bed. Plus, rest assured that there will be no warping and no curling.

- FILAMENT COMPATIBILITY: Best used for nylon, but also works well with PLA, PETG, and TPU. For high temperature materials like ABS and ASA, make sure to keep the bed hot for longer.

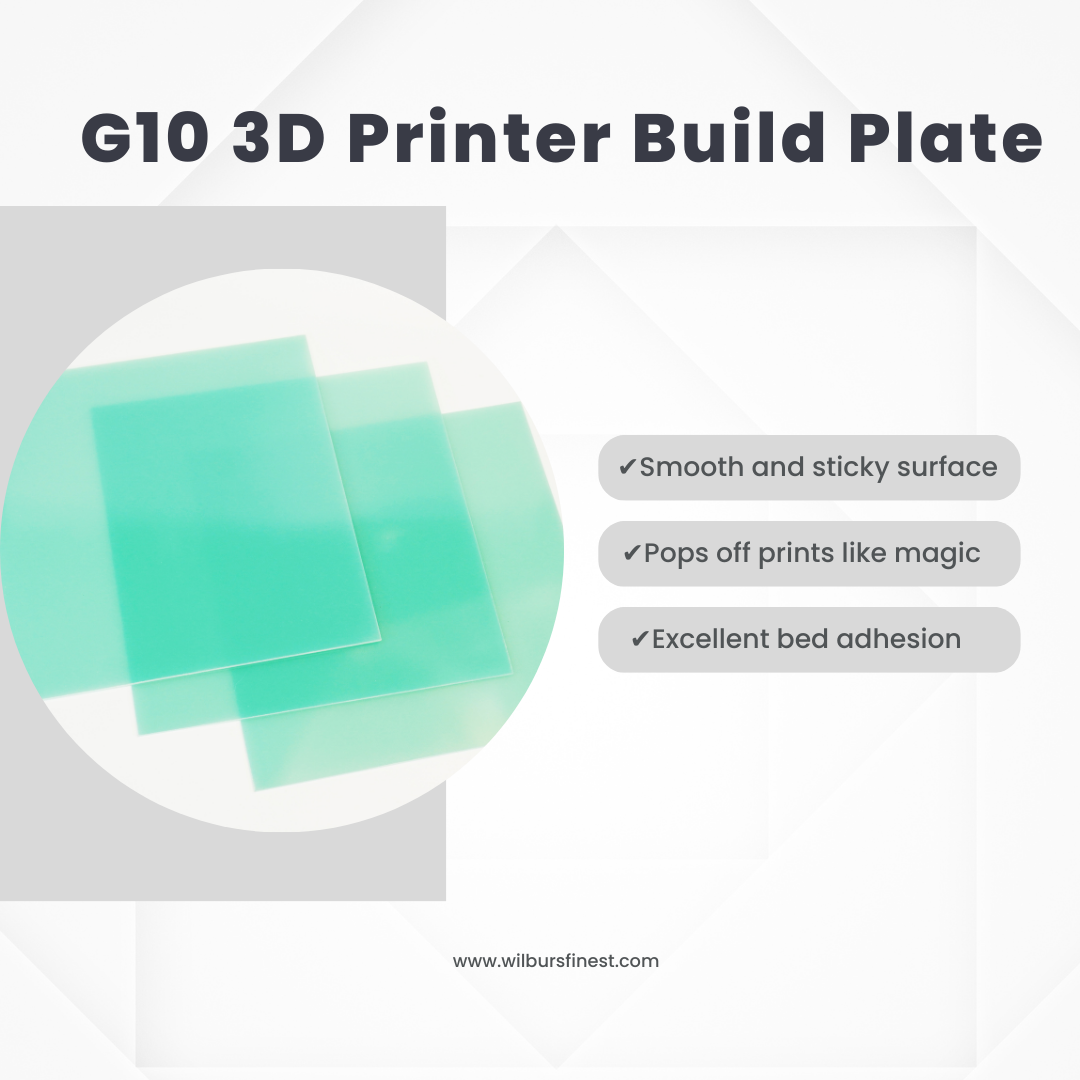

Best Material for 3D Print Build Plates

Garolite is a composite yet semi-flexible material that is reliably strong, lightweight, and has engineering and electrical properties.

Excellent Bed Adhesion

As soon as the bed heats up, your prints adhere to the surface like super glue. However, once it cools down, the prints release easily like magic.

Hassle-free Print Removal

Prints on the G10 hold up just as well as other build plate surfaces, but you'll get the most out of it when the bed cools down below 70 degrees Celsius wherein prints release themselves effortlessly off the bed.

No Warping and Curling

Easy removal of prints without scarring and white spots means you decrease the chances of having do-overs, which is great for those running a business.

Easy Installation

Install in just 5 steps. Clean, align, clip, clean again, and start printing!

How to Install the G10 3D Printer Build Plate:

- Pour isopropyl alcohol and wipe it down with cloth.

- Lay it on the printer, on top of the heated bed.

- Align it with the heated bed, and clip it using small binder clips.

- Clean it again using isopropyl alcohol and cloth.

- Start printing.

How to Remove Prints:

Most prints are able to self-release, especially with the G10. But if necessary, you may use a scraper on our build plates. Don’t worry about scratches, they will not affect the function of the build plates.

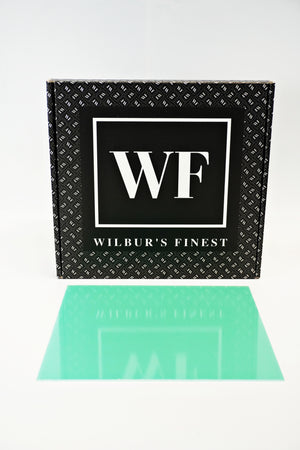

Blemished G10 Build Plate

- Regular price

- $10.99

- Sale price

- $10.99

- Regular price

-